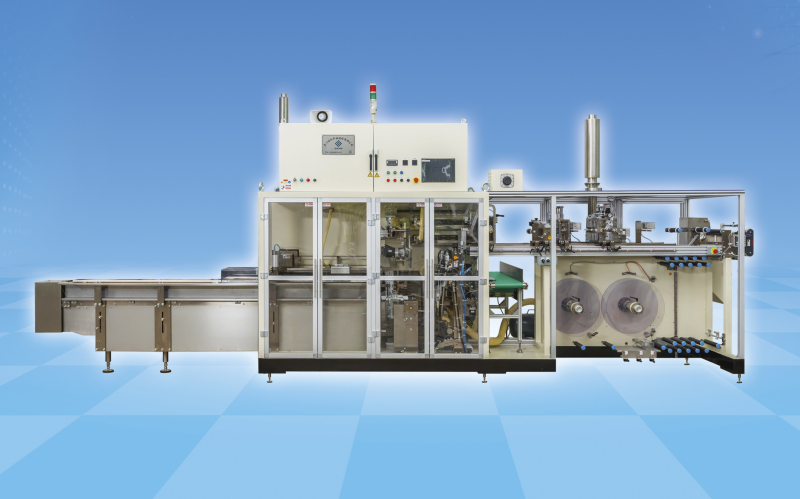

Máquina envasadora de compresas sanitarias en rollo

¿Por qué elegir GACHN?

1. Orientado a la tecnología: GACHN cuenta con un equipo técnico y de I+D de más de 40 personas.

2. La tecnología Gachn se ha utilizado para envasar más de 60 marcas de toallas sanitarias tanto en China como a nivel internacional.

3. La máquina envasadora de toallas sanitarias de Gachn ha ayudado al mayor productor de toallas sanitarias de China a capturar más del 40% de la participación de mercado en China.

4.Más de 20 años de experiencia en diseño y fabricación en el negocio de la higiene.

- GACHN

- PORCELANA

- 3 MESES

- 400 JUEGOS/AÑO

- información

La máquina envasadora de compresas higiénicas en rollo está diseñada para el envasado totalmente automatizado y de alta eficiencia de compresas higiénicas con película en rollo continuo. Ofrece una calidad de sellado estable, un corte preciso y una alta velocidad de producción, lo que la hace ideal para fabricantes de productos de higiene que buscan soluciones de envasado rentables y fiables.

Descripción

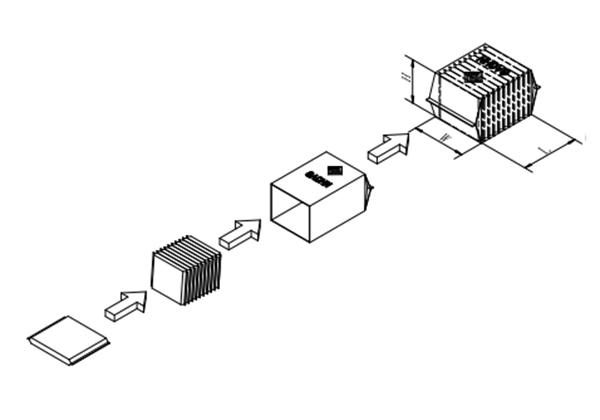

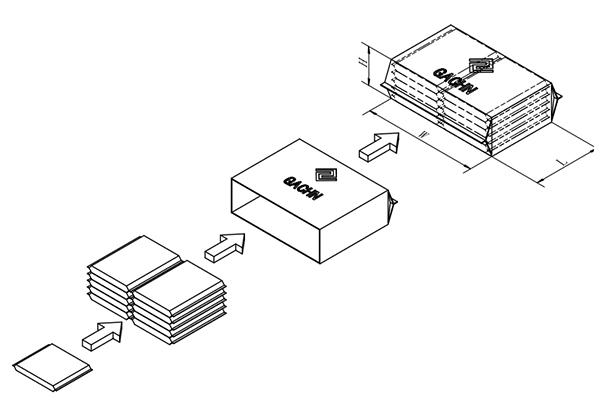

embalaje de compresas sanitarias de una sola pila

embalaje de compresas sanitarias de una sola pila

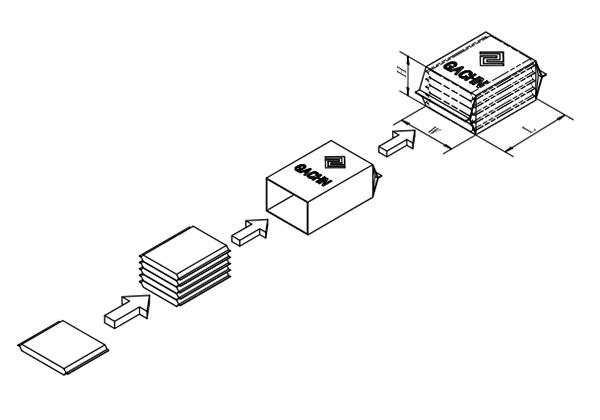

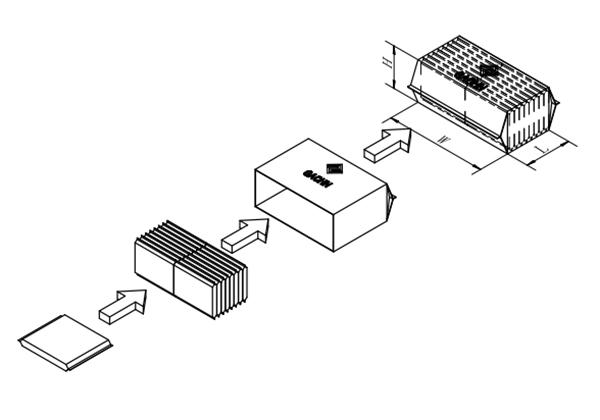

Embalaje de dos pilas de toallas sanitarias

embalaje de compresas sanitarias de doble capaParámetro técnico

| Velocidad de empaquetado | 110-120 paquetes/min |

| Eficiencia de producción | ≥95% |

| Relación de producto terminado | ≥98% |

| Medida de la toalla sanitaria | Basado en los requerimientos del cliente |

| Espesor del paquete de una sola capa | 40~70 μm |

| Número de toallas sanitarias que dispone | 5~20 piezas |

| Material de embalaje | Película de PE, película recubierta de aluminio, película compuesta |

| Método de embalaje | Bolsa en rollo o bolsa prefabricada; Vertical u horizontal |

Características especiales

1. La máquina envasadora se integra perfectamente con la computadora central, lo que permite una operación totalmente automatizada que optimiza el proceso de envasado y aumenta la eficiencia. Esta conexión fluida garantiza que no haya interrupciones ni retrasos en la línea de producción, lo que resulta en una producción más consistente de productos envasados.

2. Si bien el uso de la técnica servo integral permite que la máquina funcione a mayor velocidad, también prioriza la precisión y la estabilidad del empaque. Esto significa que los fabricantes pueden lograr una mayor productividad sin sacrificar la calidad de sus productos envasados, lo que en última instancia se traduce en una mayor satisfacción del cliente y confianza en la marca.

3. La inclusión de componentes intercambiables no solo mejora la comodidad durante la operación, sino que también simplifica los procedimientos de mantenimiento. Al poder intercambiar fácilmente los componentes según sea necesario, se minimiza el tiempo de inactividad y se mejora la eficiencia general del equipo, lo que se traduce en ahorros de costos para los fabricantes.

4. Con un sistema automatizado que gestiona la organización, el apilado y el empaquetado de las toallas sanitarias, se elimina por completo la necesidad de mano de obra en estos procesos. Esto no solo reduce los costos de mano de obra, sino que también garantiza la consistencia en la presentación del producto y minimiza los posibles errores que pueden ocurrir al recurrir a mano de obra para estas tareas.

Complementos opcionales:

Sistema de codificación de fecha/lote

Dispositivo formador de muescas de fácil desgarro

Configuración de embalaje multilínea

Inspección de productos en línea (peso, tamaño, detección de metales)

Conexión de línea de estuchado automático

Aplicaciones:

Fabricantes de toallas sanitarias

Fábricas de productos de higiene femenina

Marcas de productos de higiene OEM/ODM

Líneas de envasado automatizadas de gran volumen

□ Mitsubishi Yaskawa 、 □ Siemens 、 □ Schneider 、 □ AB 、...more